How We Help Our Clients

By maintaining a narrow focus, we offer an unmatched depth of expertise in four key areas that ultimately determine both the short- and long-term success of a product.

Product Program Management

It all starts with your products, or assets, as they drive the value in your company. We help unlock the potential of your assets by deploying best practices of program management coupled with our experienced, pragmatic approach to developing biologics. Priorities can change quickly so the business processes require both structure and agility to be successful.

For any program we manage, we ensure each critical phase is complete as defined below:

- Strategic Phase:

Determines the optimum strategy to realize the product and program’s objectives in a way that maximizes benefit, minimizes business risk, meets timelines and minimizes impact to company resources

Deliverables may include a program requirements document, an initial TPP, milestone schedule, partner proposals (CROs, CDMOs), cost estimates, program deliverables list, and functional strategy documents - Planning Phase:

Details out the approved strategy with a plan and approach that ensures the requirements are met

Deliverables may include a Project Execution Plan, budget estimates, partner SOWs, risk register, resource plan and detailed schedule - Execution Phase:

Delivers the plan within the approved budgetary and schedule guidelines

Deliverables may include detailed finalized SOWs, change control documentation, KPIs and progress reports to governance

Primecore can assist at any level

Our team can help at any phase of a program – either starting one new or helping with the final stages of execution. We find that often the upfront steps are missing or skipped, which creates confusion for the team. Helping to organize the program and establishing the requirements can be of a great value no matter what phase you are in.

Services include

- Product strategy development

- Product program management

- CMC program management

- Strategic portfolio management

- CMC subject matter experts (SMEs)

- Business case development

- Program and project benchmarking

- Establish best practices

- Risk management

Network and Supply Strategy

The commercial and business strategy needs to be translated into an operations strategy for each product and for the supply network. We help our clients develop the Operations strategy and then determine the optimum network based on requirements and guiding principles. Individual product CMC strategies and life cycle plans are then developed to align with the overall network.

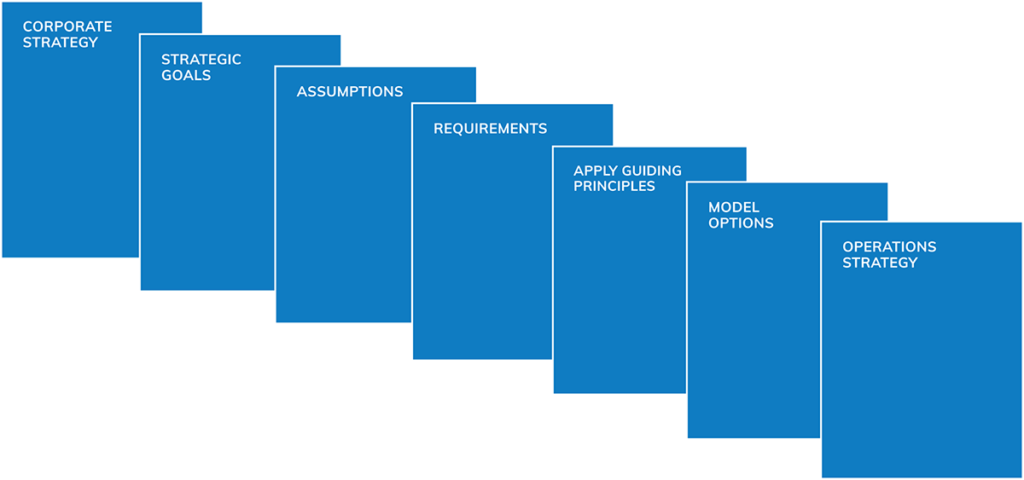

Operations Strategy (network and product) is developed using a framework that first establishes the corporate strategy and strategic goals. From these, the Operations strategy is derived using a logical progression of steps:

We help our clients with every step of the process and find that focusing on the Requirements and Guiding Principles are critical for establishing a pragmatic and business aligned strategy for Operations.

Services include

- Network guiding principles

- CMC and manufacturing strategies

- Capacity modeling and planning

- Establish business processes

- Facilities strategy and space planning

- Make vs. buy analysis

- Decision analysis and probabilistic modeling

- CDMO selection

Capital Program Management

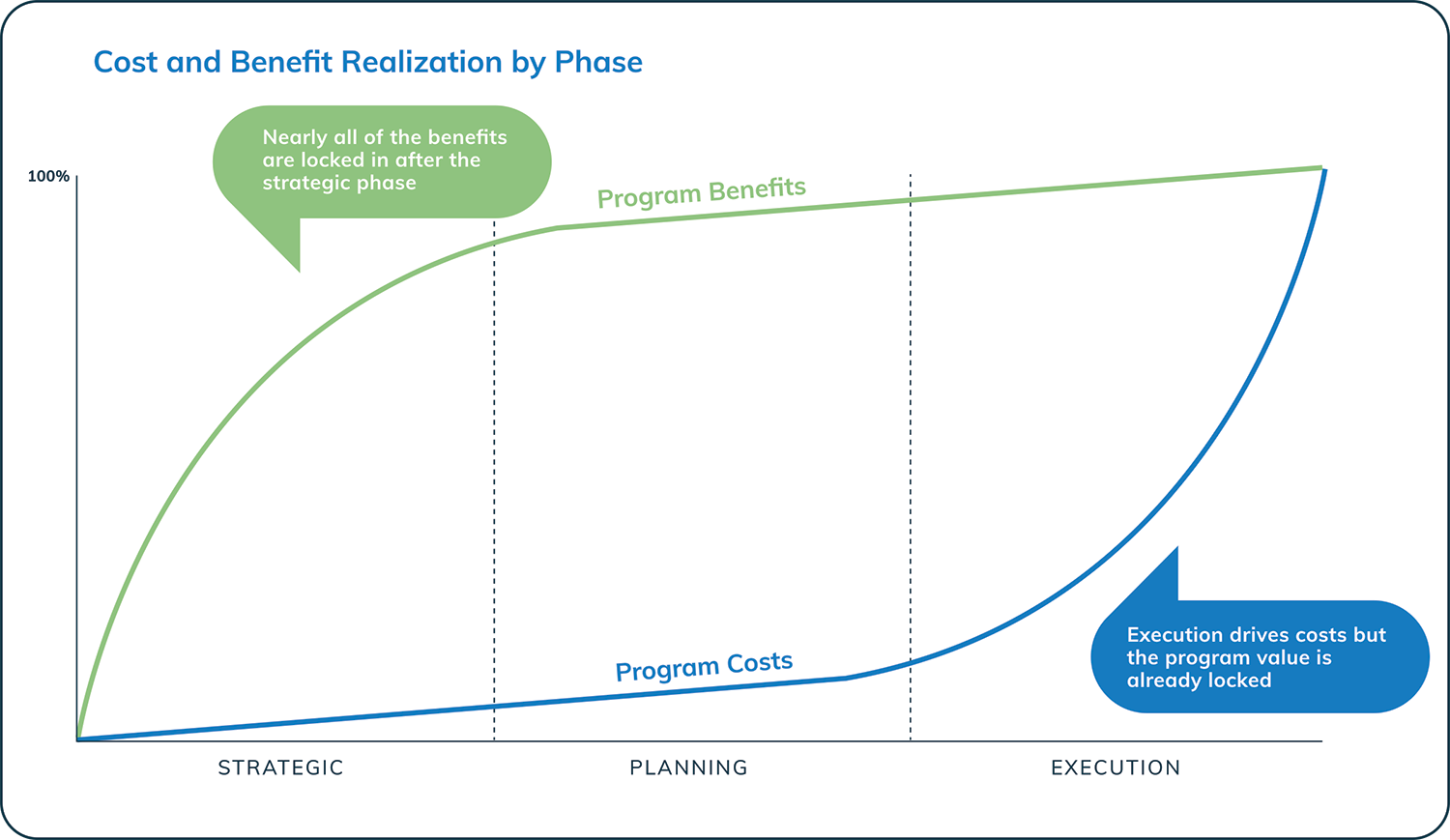

Delivering capital programs is where our best practices were developed. The greatest value of any capital project is typically locked in at the concept phase which is why we focus intensely on upfront project definition. The investment must be aligned with the business case and ensure the program benefits are realized upon completion.

The client company’s value is all in their products, but products need what we call key enablers to reach their potential. Often times these are physical assets that need to be built such as laboratories, a vivarium, process development space, or a GMP manufacturing facility. Managing the capital programs to meet the needs of the products and ultimately the needs of the business is critical for success.

At Primecore, we focus intensely on the Strategic and Planning Phases as that is where we see nearly all of the program’s value achieved. Interestingly, the phases with the least cost impact deliver the most value yet are often overlooked.

Similar to product programs, we follow the same schema for capital – we ensure each critical phase is complete with a formal stage gate and approved charter before advancing to the next.

Services include

- Feasibility studies

- Program management

- Project execution

- Owner’s representative

- Project controls

- Benchmarking

- Stage gate models & guidelines

- Risk management

- Lessons learned workshops

Operations and Continuous Improvement

Your facilities are key enablers to your products success and require optimization to deliver on the investment. As processes change or new products are introduced, it is important to reevaluate your operations and ensure the product program requirements are met now and in the future, always accounting for the variables in-between products.

Operationally, it’s important to instill an Operational Excellence mindset in order to get more out of your network, facility or processes. That is why we approach operational based assignments with a focus on both continuous improvement as well as Change Management. Ultimately, operational excellence is not just about reducing costs or increasing productivity. It’s about creating the culture that will allow our clients to achieve long-term sustainable growth. Our team deploys the principles of change management while deploying Six Sigma tools or implementing Lean Manufacturing, as both are required for long term success.

We have helped clients analyze their process and facilities, modeled plant and network capacity and helped Operations teams meet the increasing demands for the product. We routinely evaluate impact vs. effort and, in particular, categorize opportunities based on regulatory requirements as well. Opportunities to run smarter without a process change are always more favorable.

Business processes also need to be implemented or optimized as organizations and portfolios grow. We have helped clients with their financial reporting, maintenance programs, and S&OP processes among others. It is important that Operations business systems are not person based but sustainable and scalable as the company grows.

Services Include

- Process modeling and optimization

- Capital equipment lifecycle management

- Value stream mapping

- Implementation of business process

- Sales & operations planning

- Facility optimization and space planning

- Laboratory throughput analysis

- Scale-up and scale-out management

- Tech transfer program management

- Organizational design